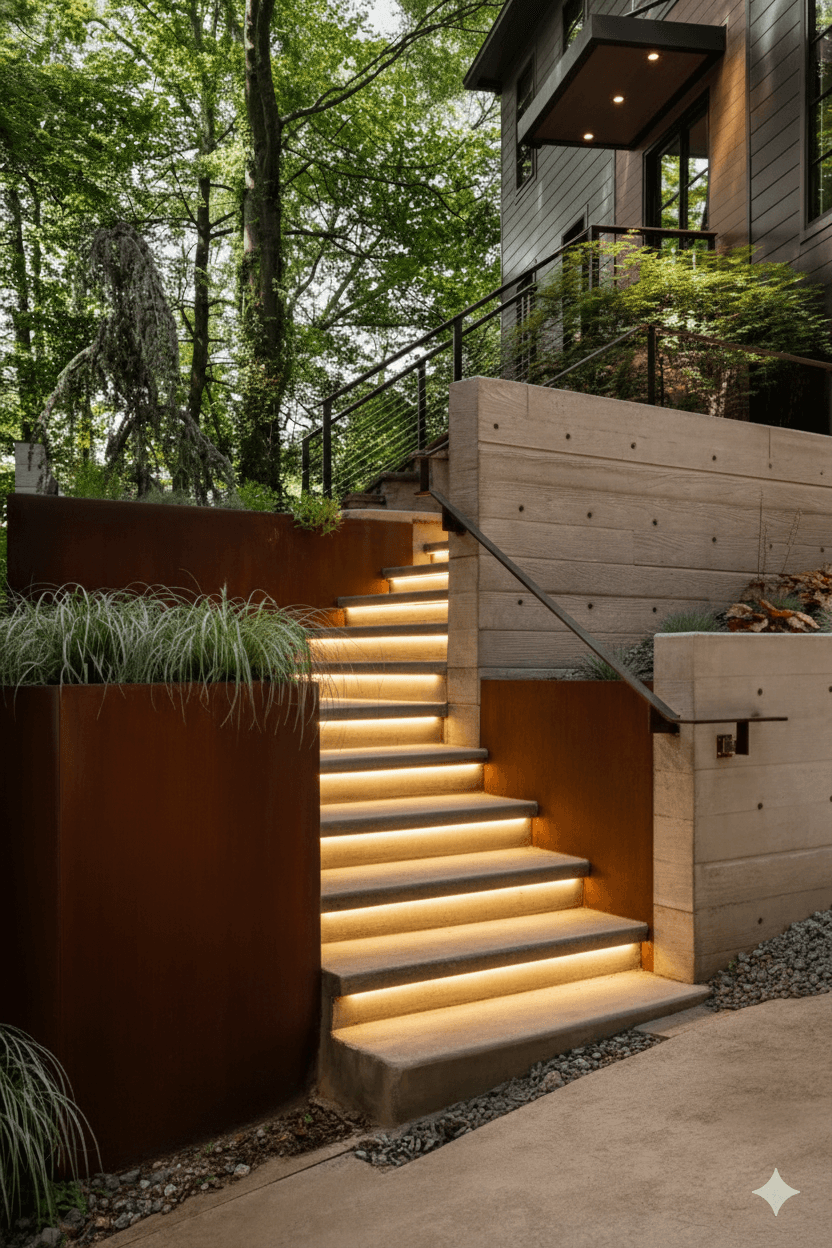

Build / Installation

Project management

1500 sq ft.

The complexity of this project was rooted in three primary constraints: site access, materiality, and critical phasing. With no civil engineers involved, Atlanta Fine Gardens became the primary problem-solvers –determining elevations, rise-and-run specifications, landing depths, and material fastening details on-site.

The team’s keen eye for design ensured that the constructed reality honored the spirit of the original, beautiful rendering. This meant successfully marrying required trades such as steelwork, concrete forming, and civil works (drainage/irrigation)— all in a highly confined area.

Restricted site access

Located on a main street, the site allowed only one truck at a time, making logistics and deliveries difficult. Almost all excavation, backfilling, and material transport had to be done by hand.

Specialized finishes

The design demanded highly specialized finishes, including cast-in-place concrete walls using USA form liners for a refined texture, integrated lighting within the concrete flatwork, and a rare pigmented, exposed aggregate concrete finish.

Critical phasing

All elements—Corten steel walls, planters, handrails, and multi-phased concrete pours—were critically dependent on one another and had to be built sequentially from the lowest point up, demanding strategic organization.